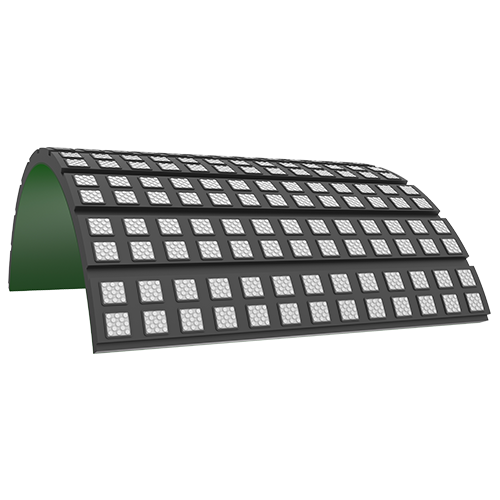

It is suitable for pulley lagging of long-distance and high-speed belt conveying equipment. It has good anti-slip ability, and prolongs equipment startup time by reducing the frequency of lagging replacement.

1. Combined with DCCD® cleaning agent, metal treatment agent and cement, it can produce the maximum bonding strength and is safer to use;

2. It will not hurt the non-working surface of the conveyor belt, which is more friendly to the conveyor belt;

3. Provide >50000 hours service life under normal working conditions;

4. It can be used in high belt speed, muddy, ≥ 3000t/h conveying capacity and other working conditions;

5. Unique ceramic tiles bonding technology, ceramic tile is not easy to fall off;

6. No need to grind the CN layer.

|

Ceramic Tiles |

|

|

AlO,Content |

92%,95% |

|

Volume Density |

3.65~4.5g/cm |

|

Tensile strength |

20 Mpa |

|

Compressive Strength |

200 Mpa |

|

Hardness (Mohs) |

>9t |

|

Water Absorption |

<0.02 |

|

Abrasion |

<120 mm |

|

Rubber |

|

|

Polymer |

NR/SBR |

|

Specific Gravity |

1.2+/-0.03 |

|

Shore a (hardness ) |

65+/-5 |

|

Elongation at break |

400% |

|

Tensile strength. |

17 N/mm² |

|

Abrasion Loss |

<120mm |

|

--- |

--- |

|

Commodity |

Thickness.mm |

Width.mm |

Length.mm |

|

Normal Ceramic Lagging |

12 / 15 / 18 / 20 |

500 |

Customized |

|

Flame Retardant Ceramic Lagging |

12 / 15 / 18 / 20 |

500 |

Customized |