Service scope

It can meet the technical service of non dismantling state of belt conveyor system or on-site roller coating construction.

Service indicators

Suitable for the construction of various specifications and models of drive, steering, heavy hammer, tensioning, and roller wrapping technology.

Construction time

According to the manual operation of 630×1000 drum, the normal operation time from scraping glue to polishing and pasting glue should not exceed 16 hours (excluding loosening hammer, tensioning belt, and equipment recovery time).

Start preparing

Firstly, confirm the speed of the conveyor belt, the on-site environment, and the load-bearing situation. Choose the surface shape and thickness of the wear-resistant rubber plate, measure the length and diameter of the rubber drum to be wrapped, calculate the material consumption, and cut the material.

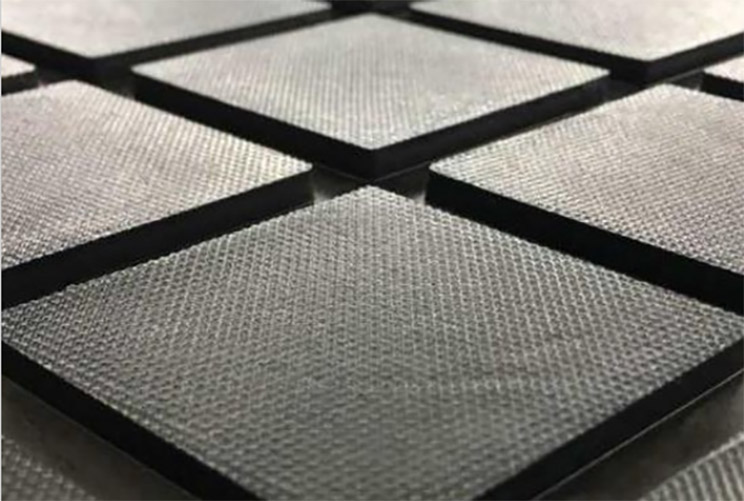

Drive the drum wheel, it is recommended to use a diamond slotted rubber plate.

Guide wheel, tail wheel, and tension wheel: It is recommended to use a flat rubber plate with no grooves on the surface.

Using grooved drum wrapping material can enhance the self-cleaning of the drum and prevent conveyor belt deviation.

Essential tools: caliper for measuring thickness, tape measure, folding ruler, marking powder line rope, rubber marking pen, Danka screwdriver, layering knife, layering peeling hook, cleaning brush;

Personal protective equipment: safety helmet, work clothes, steel helmet shoes, gloves, flashlight, goggles, earplugs, work notebook, work permit.

Detailed explanation of the process flow of cold vulcanization drum rubber wrapping

1. Shovel glue: Clean all the existing film on the drum completely.

2. Grinding: Use tungsten steel grinding discs and fiber grinding discs (16K-24K) to smooth the surface of the drum;

3. Cleaning: Use specialized DCCD high-efficiency cleaning agent to clean the surface of the drum twice. Maintain a ventilated environment during the cleaning process;

4. Brush metal primer: evenly apply DCCD metal treatment agent, requiring sufficient drying;

5. Apply cold vulcanized adhesive: Apply DCCD cold adhesive evenly twice, and ensure it is fully dried.

6. Treat the surface of DCCD wear-resistant rubber sheet and apply DCCD cold adhesive evenly, keeping it clean.

7. Adhesive bonding: Stick the wear-resistant rubber plate coated with cold adhesive DCCD onto the surface of the drum, align it with the marking, compact it, and exhaust the air;

8. Joint treatment: Use DCCD sealing adhesive or DCCD quick repair adhesive at the joint of the rubber plate. The joint treatment angle is about 45 degrees, which is suitable and neat.

9. The perfect DCCD cold vulcanization roller coating is completed.

Effect of DCCD drum after cold vulcanization and rubber coating:

Smooth the roller coating and restore the working surface function of the roller;

There is no adhesion on the surface of the drum, and the belt wear is expanding;

No wear and tear occurs, no longer damaging the belt frame material, and there are no safety hazards;

Reinstall the cleaner to clean the belt, greatly reducing the belt load;

The belt runs stably without any shaking or deviation.

Precautions and common problems for roller coating:

Check the usage date of DCCD cold vulcanized products and the CN uncured layer of wear-resistant rubber sheets.

Bubble treatment: puncture and release small bubbles, cut atmospheric bubbles into square blocks for treatment.

The drum after being coated with glue needs to be tested by professional personnel before it can be put into operation.

Drum shaking issue: 1. Check if the machine components are complete first, 2. Belt issue, 3. Check if the drum wrapping is standardized.

Adhesive detachment issues: 1. Adhesive failure, 2. Unclean, 3. Metal primer not applied, 4. Wear resistant adhesive plate too thin, 5. High belt speed, 6. Drum not rotating, 7. Joint treatment not done {with water}, 8. Oil contamination.