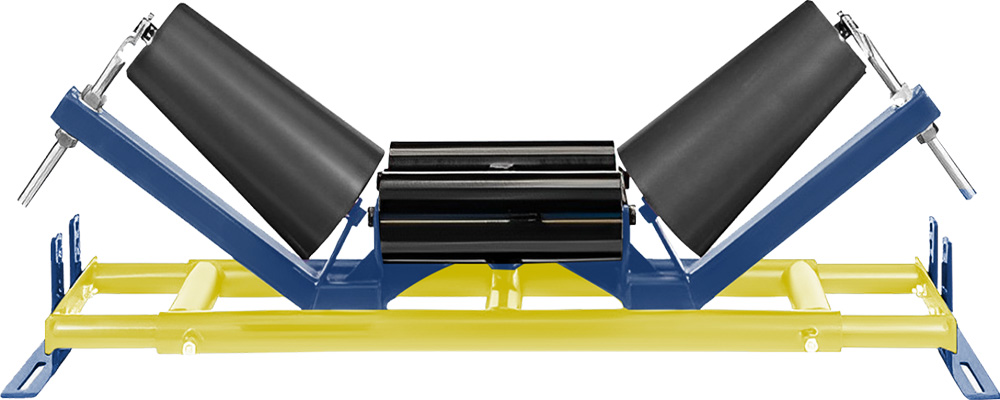

DCCD has launched a heavy-duty conveyor belt aligner. The conveyor belt aligner adopts another high-performance tracking idler roller, which can be applied to wider conveyor belts and more demanding conditions. The conveyor belt aligner adopts DCCD’s “rotation and tilt” technology design process, which can be used in any application that requires tracking to prevent damage to the conveyor belt or conveyor frame, including one-way and reverse conveyor belts.

The unique rotation and tilt functions ensure that the conveyor belt is kept away from the frame and the material is always on the conveyor belt, without the need for any sensors or edge rollers. The conical end on the roller can drive the rotating and tilting mechanism, and the two forces can quickly move the conveyor belt back to the center position. The demand for correctors that can handle wider conveyor belts and more demanding conditions prompted us to develop DCCD conveyor belt correctors. DCCD’s products also use unique rotation and tilt technology, but are designed specifically for high load working environments.

The DCCD conveyor belt aligner can be used for almost any heavy-duty application of vulcanized conveyor belts or mechanical belt buckle conveyor belts, with a maximum tension of up to 2800 PIW, including wet and dry conditions, conveyor belts with damaged or worn edges, and conveyor belts that deviate to one or both sides.

Suitable for conveyor belts with a width of 40 “to 90” (630 mm -2200 mm), the DCCD conveyor belt aligner can be installed as a standard “pull-up” installation piece. The installation method is to exchange its position with the existing return idler roller, or the aligner can be installed on the clean side of the conveyor belt, using the material free lower surface as the contact area of the conveyor belt aligner. The simple and adjustable mounting bracket ensures fast and accurate installation using any method.

The DCCD conveyor belt aligner also has a polyurethane or rubber roller sleeve to ensure long-lasting performance under the most demanding conditions. After verification, the service life of DCCD with polyurethane roller sleeves is 2-5 times longer than that of rubber roller sleeves, and it can also provide the gripping force required for effective driving of rotating and tilting mechanisms.