The automatic locking device ensures the cleaning efficiency of the conveyor belt at all times, and avoids the uncleanness of the conveyor belt caused by the lack of manual adjustment of the locking device.

Maximum belt speed: ≤ 7.5m/s;

Maximum applicable temperature: 210℃ ;

Minimum applicable temperature: minus 35℃ ;

Maximum belt width: ≤ 3m;

Conveyor belt reversible: yes

Grain transportation, coal, cement plants, thermal power plants, quarries, mines.

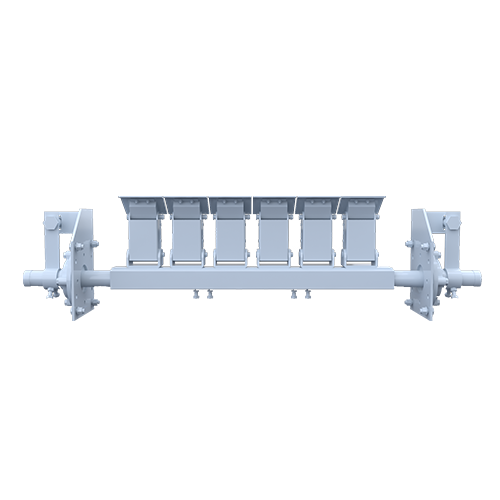

1. Automatic adjustment during operation: There is no need to manually adjust the locking device, and the cleaner has its own automatic locking adjustment device, which can always ensure that the cleaner blade sticks to the surface of the conveyor belt.

2. Higher cleaning efficiency: The segmented design is adopted, and the automatic locking device will automatically adjust the angle according to the change of the flatness of the conveyor belt surface during operation to provide better cleaning effect.

3. The alloy blade is easy to replace: when the blade is replaced, it is only necessary to remove the 2 bolts under the blade, and there is no need to replace the blade base, which is convenient and economical to replace.

4. Stronger impact resistance: The sturdy blade tipping plate design is not afraid of the impact of large stones, and can tilt large stones into the blanking chute.

|

Belt width.mm |

Blade width.mm |

Blade quantity |

|

650 |

580 |

4 |

|

800 |

725 |

5 |

|

900 |

870 |

6 |

|

1000 |

870 |

6 |

|

1200 |

1160 |

8 |

|

1400 |

1305 |

9 |

|

1600 |

1450 |

10 |

|

1800 |

1595 |

11 |

|

2000 |

1740 |

12 |