Traditional drum rubber wrapping method – hot vulcanization casting rubber

The rubber coated drum is an important component of the belt transportation system, and the rubber coating of the drum is the first element to effectively improve the operation of the conveying system. In China, most belt conveyor systems still use the original high-temperature hot vulcanization casting rubber for drum wrapping. Due to the production process, formula, and other reasons of hot vulcanized rubber, there are many disadvantages to the hot vulcanized rubber on the drum:

1、Hot vulcanization casting rubber is subjected to high-temperature vulcanization in a vulcanization tank, and the vulcanization pressure is achieved through gas pressure. The vulcanization pressure is less than (6-8 kg/cm2), resulting in low compactness and poor wear resistance of the vulcanized product.

2、Hot vulcanized rubber is vulcanized under low pressure, and there must be a large amount of sulfur in the formula. Rubber containing excessive sulfur gradually hardens in the air. When the hardness is too high, the roller coating loses its key role in increasing friction.

3、The connection between the hot casting adhesive and the drum is made by the transition layer and the metal, which has low strength (3-10N/mm) and often causes cracking between the transition layer and the metal (a certain mine has experienced the phenomenon of new drums falling off during loading and unloading). When repairing the damaged position of the drum, gently prying the transition layer with a screwdriver will cause it to separate from the metal, which will inevitably shorten the service life of the adhesive.

4、High hardness, poor self-cleaning ability of the drum.

Data shows that the service life of hot cast drum rubber in mines with a production capacity of over a thousand tons is only 3-5 months.

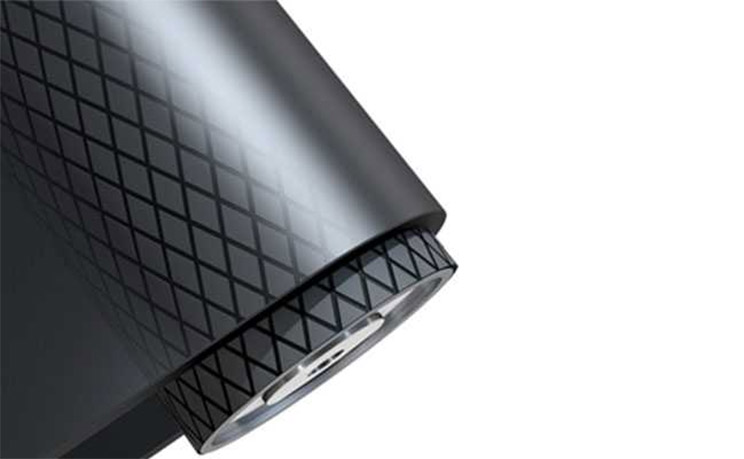

The modern encapsulation method adopted internationally – cold vulcanization encapsulation

Cold vulcanization drum rubber coating is a new type of drum rubber coating method adopted compared to traditional drum hot vulcanization casting rubber, which has been widely used. The service life is 3-5 times longer than the average value of the hot cast rubber drum. Advantages of cold vulcanization encapsulation:

1、Convenient, fast, and do not require special operation workshops.

2、Cold pack adhesive material is easy to use and suitable for on-site emergency repairs and daily maintenance.

3、Cold pack adhesive materials have low usage, stable quality, and lower maintenance costs.

4、Operating at room temperature and using professional tools will not cause any new damage to the belt or equipment.

5、Cold bonded adhesive has a long service life and can match the maintenance cycle of large equipment.

6、Short downtime minimizes the impact on production.

7、Segmented solution, long-term use, saving procurement costs.

DCCD company has been committed to researching and promoting the latest technology for conveyor system maintenance, and has proprietary room temperature (cold) vulcanization bonding technology and specialized rubber sheet material products. It can effectively solve common maintenance problems such as belt wear, belt deviation, belt tearing, belt breakage, local belt aging, belt cuts, and belt delamination caused by drum slippage. Effectively prevent the occurrence of conveyor belt deviation accidents. DCCD cold vulcanization products greatly increase the running time of the belt and reduce the cost of downtime maintenance.